We understand many operations do not have a need for full-time maintenance personnel - so here are some key points to get you back up and running ASAP

How to prevent breakdowns?

Breakdowns can occur frequently in machinery and equipment, but they certainly aren’t considered normal.

Keep on top of manufacturer recommended maintenance schedules

Lubricating/greasing with the correct lubricant can be one of the most cost effective preventative maintenance

Regular cleaning and ensuring operators are trained

What to do when you experience a breakdown?

Stop/Isolate the machine immediately to prevent further damage

Document what happened/how the machine was being operated when it failed

This will often help reduce diagnostic time and get you back online faster

Call OJ Mechanical for fast and efficient service

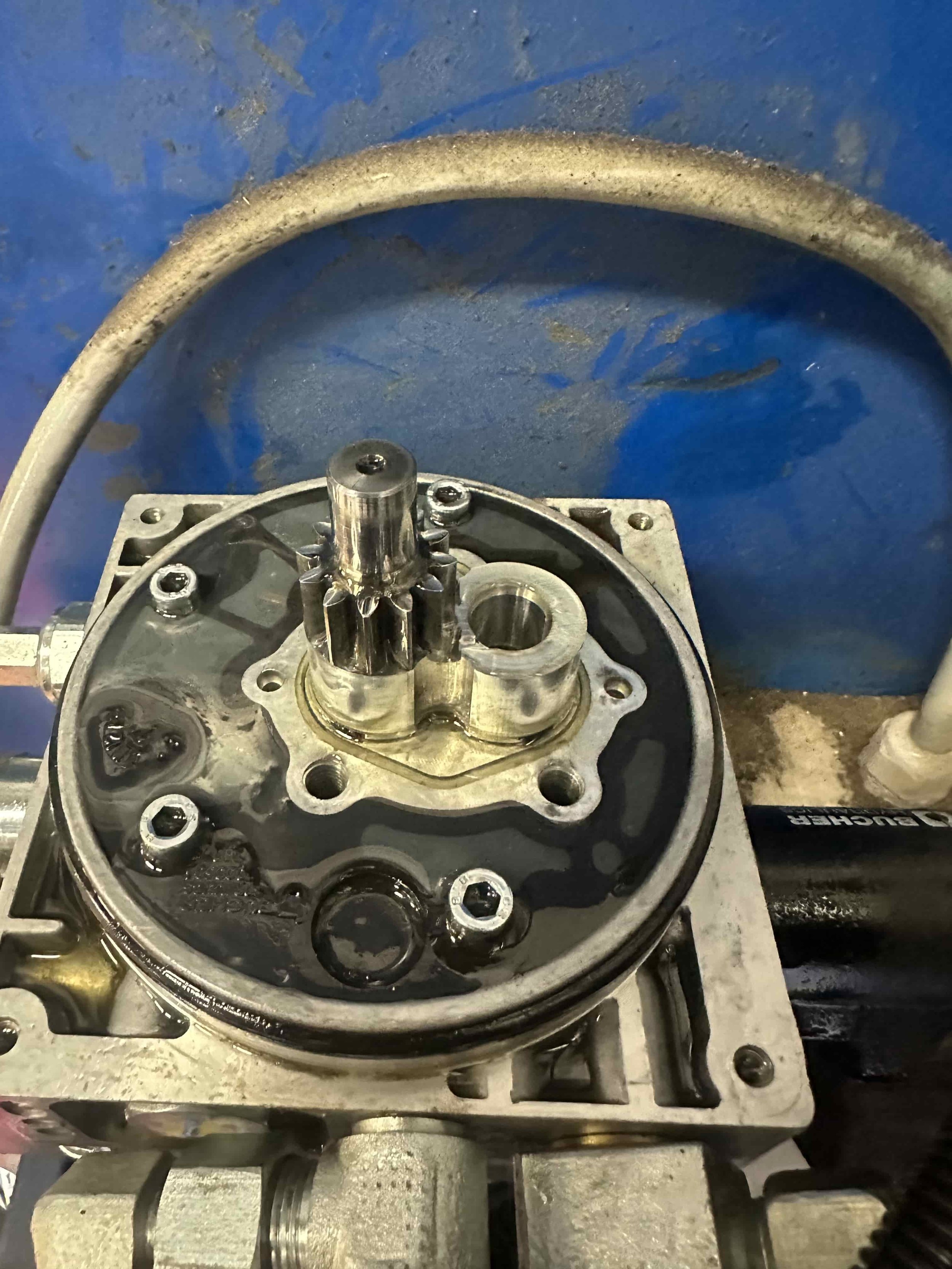

Common Issues with Hydraulic Systems

Overheating

Typically due to insufficient cooling or low oil levels.

Ensure proper ventilation and check oil levels regularly

Leaking Hoses

Often cause by damaged seals or wear.

Isolate the machine and bleed the hydraulics by manually cycling the valves

Check if the connections are tight and get damaged hoses replaced

Slow Hydraulic Operation

May be caused by low fluid levels or clogged filters.

Check and refill hydraulic fluid and clean or replace filters

Air in the System

Air bubbles can cause erratic movements.

Bleed the hydraulic system to remove trapped air

(Should only be performed by qualified personnel)

Want to know about our equipment?

What we carry with our service vehicle:

Hand & Powered Tools: A full range of hand & powered tools to perform various mechanical repairs.

Specialty Tools for Hydraulic Repairs and Precision Fitting: Tools designed specifically for hydraulic systems and precision fitting work.

Battery Pack/Jump Starter: For dealing with battery-related issues in machinery.

Spill Kits: To handle hydraulic or oil spills safely and in compliance with environmental standards.

Grease Gun: Useful for maintaining machinery and components that require regular greasing.

Basic Electrical Supplies: Wire connectors, fuses, and multimeter for 12/24V electrical troubleshooting.

Spare Filters: Commonly used hydraulic and engine filters for quick replacements.

Portable Air Compressor: To assist with inflating tires or powering pneumatic tools.

Assorted Fasteners and Consumables: Bolts, nuts, washers, and other essential consumables for on-site repairs.

Pressure Testing Kit: To verify system integrity and diagnose hydraulic issues.

Fire Extinguisher: For safety in the event of any fire-related emergencies.

What we carry in our mobile hydraulics workshop:

Hoses, tails & fittings from 1/4” to 1 1/2” for

BSPP & BSPT

JIC

SAE Code 61 & 62

ORFS

Metric Heavy & Metric Light

JIS Metric

Adaptors to NPT, CAT, UNO and Quick Connect and Flat Faced Couplings

Hoses

1/4” 2-Wire (5800PSI)

3/8” 2-Wire (5000PSI)

1/2” 2-Wire (4257PSI)

1/2” Multispiral (6100PSI)

3/4” 2-Wire (3120PSI)

3/4” Multispiral (6090PSI) (Xtreme)

1” Multispiral (6090PSI) (Xtreme)

1 1/4” Multispiral (6090PSI) (Xtreme)

1 1/2” Multispiral (6100PSI)

As a minimum our fitters have:

Cert III Engineering - Mechanical Trade

HRWL:

EWP

Dogging

Basic Rigging

LF

Other tickets include:

Working at heights

Confined Spaces

C Class Drivers Licence

Please contact us directly for a copy of the following:

Qualifications and Certificates

Our most up to date Safe Working Method Statement (SWMS)

Business/Public Liability Insurance

Workcover Certificate of Currency